OEM Stamping

Professional OEM stamping service provider

Welcome to ACHIVE. We have more than 20 years expertise on stamping and can provide professional OEM service to customers around the world, who needs metal spare parts in giant engineering machines, mining equipment, sling equipment and so on. Supported by dedicated R&D team and well-established manufacturing system, we can offer flexible solutions to make specific products from customers’ own designs.

Our products

our OEM Stamping pruducts

Our stamping products are being widely used in engineering machinery, railway and mining equipment. Different grades/properties of steel are being used to meet industries’ regulations or customers’ specific demands. For example, regular grades of steel are used for general purpose applications, low-Carbon high strength steel is widely used in scaffold, ‘and deep-drawing grades are popularly used in mining. Our aim is to make correct products at competitive costs by using correct material and most effective and efficient production methods.

choose achive

Professional OEM stamping service provider

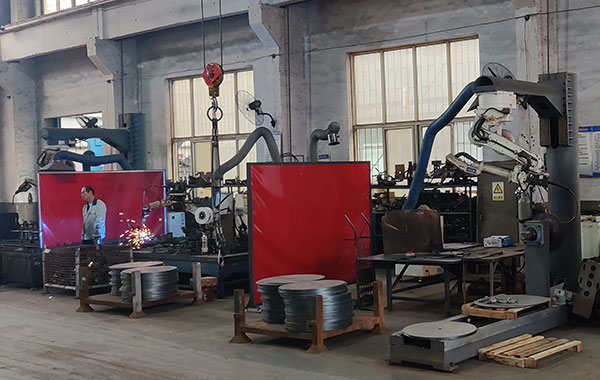

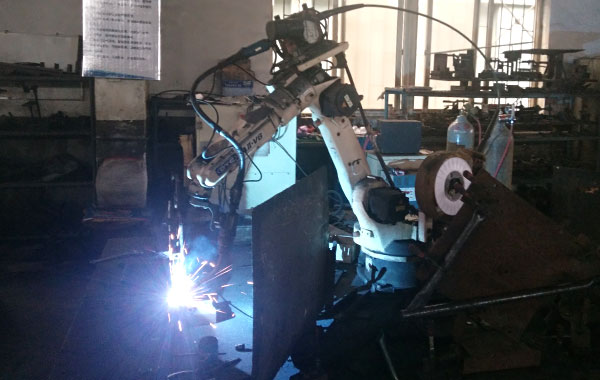

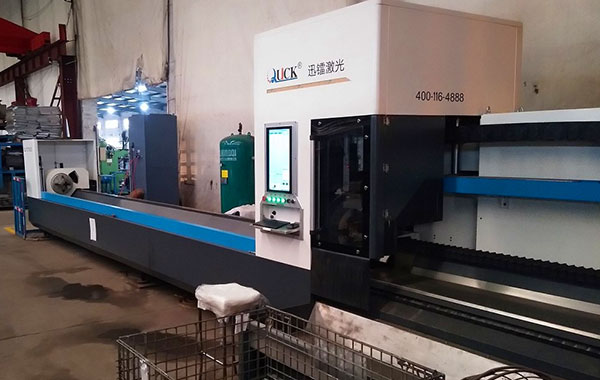

Equipment

We have access to stamping presses from tens tonnage to thousands tonnage hydraulic. We also keeping working to continuously upgrade equipment to improve efficiency, accuracy, and capacity.

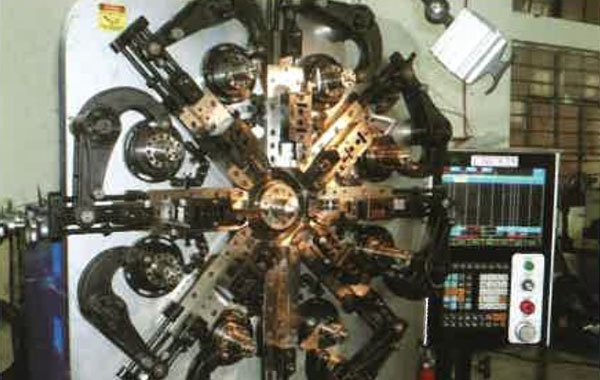

Technology

Our engineers and workers have rich experience on stamping to produce parts in wide ranges of shapes/sizes/weights. We can design and make tooling effectively to produce parts of high quality at reasonable costs.

Procedure

Strictly following ISO QC requirements, we set up our QC system and procedures in full production process — from raw material flowing in, to manufacturing, to final inspection, and to packing and shipping.

Trustworthy

We successfully established solid and long-term cooperation with both suppliers and customers. Work together to win-win!