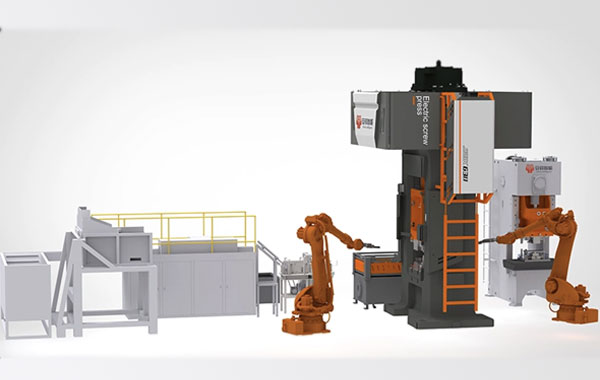

With advancements in technology, forging techniques continue to innovate to meet the increasingly complex industrial demands. The following are key development trends in forging technology:

- Precision Forging Technology:Precision forging produces high-accuracy and complex-shaped components by precisely controlling process parameters. It is widely used in industries like aerospace and automotive, improving the performance and reliability of parts.

- Digitalization and Smart Manufacturing:Digital technologies and the Internet of Things (IoT) are transforming forging production. Real-time monitoring and data analysis, along with smart equipment, enhance production efficiency, optimize process control, and reduce defects.

- Green Forging Technology:Environmental protection has become a key focus in forging technology. Through energy-efficient equipment and exhaust treatment systems, forging companies achieve lower energy consumption and emissions, promoting sustainable development in the industry.

- Integration of 3D Printing and Forging:Combining 3D printing technology with forging processes allows for the rapid production of complex molds or pre-formed parts, improving production efficiency and reducing material waste.

- Application of New Materials:The use of high-temperature alloys and advanced materials is driving the development of forging technology in high-performance fields, particularly in aerospace and other industries, to meet more demanding working environments.

The innovations in forging technology continue to drive high efficiency, precision, and environmental sustainability in industry, providing high-quality, reliable products for various sectors.